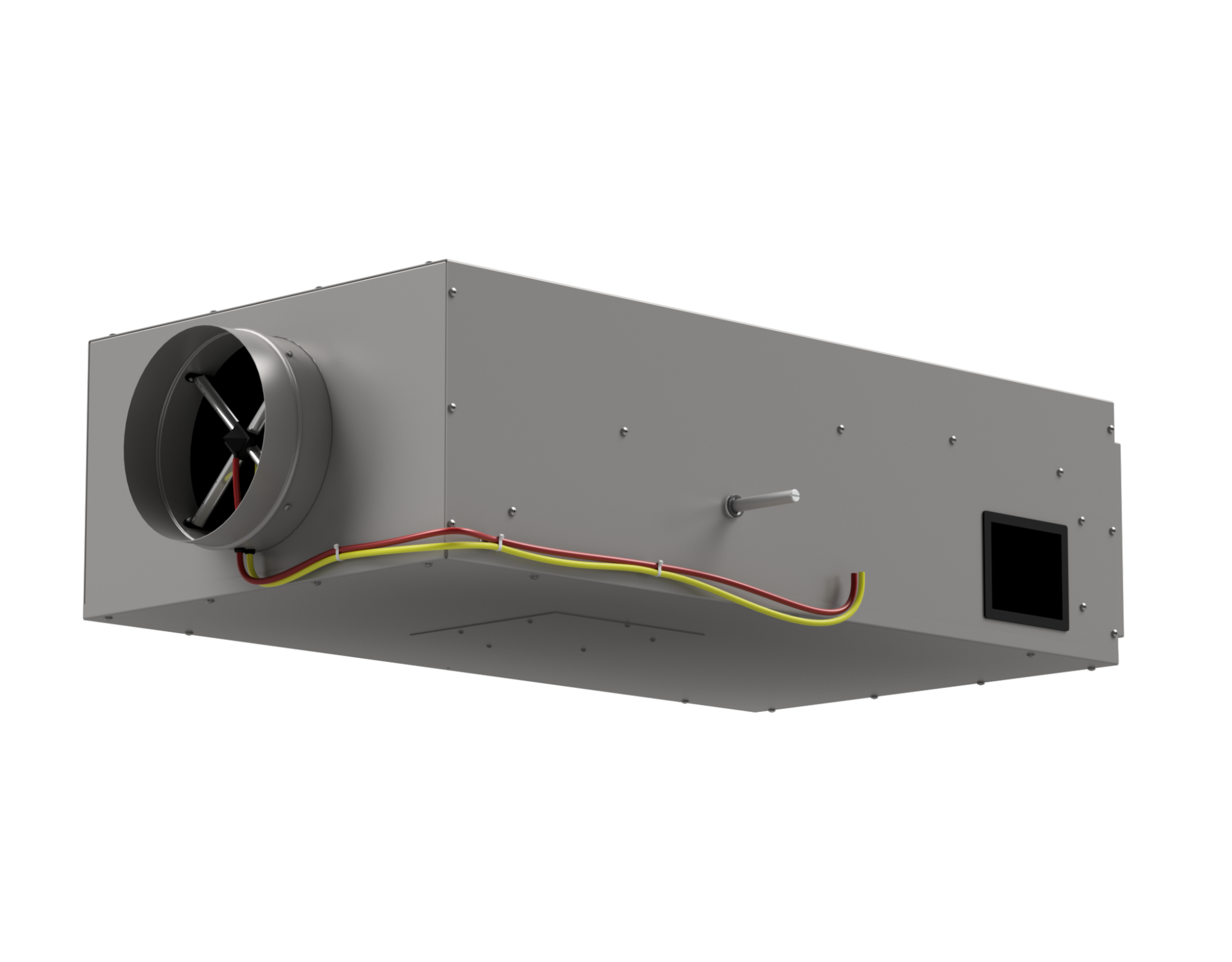

Type NV rectangular pressure-independent VAV air volume control terminals are designed particularly for systems with high variations in heat load.

The terminals induce room air and mix it with conditioned primary air, maintaining a nearly constant air volume to the room thus providing sufficient air movement necessary to maintain occupant comfort even in extreme load variations. This specific characteristic means that cold air ‘dumping’ will not occur and that extremely low primary air temperatures can be used, without producing excessive differences between the supply and the room air temperature. The primary air is controlled by the patented airflow sensor type Flo-Cross®.

The Induction VAV terminals can be used for supply air applications in new or refurbishment projects. The terminals can optionally be supplied with a distribution plenum and a built-in hot water or electric reheat coil. Alternatively VAV terminals are ideal to be used for CO2 control. Dependent of the indoor air quality, always the correct amount of fresh air will be supplied to the room. Off course the primary air handling system need to be suitable for this.

New Induction VAV project? Use the Barcol-Air selection tool AIRSELECT for easy selection!

Ceiling Induction VAV systems have all the energy savings advantages of VAV systems with the added capability of maintaining thermal comfort at very low turn-downs. The unique design of the VAV Induction terminals allows the unit to induce room air and mix it with conditioned primary air

without using a fan. The rate of induction can be adjusted by selecting varying inlet pressures, inlet volocities, down stream pressure loss and where required by the use of a damper in the induction port.

A conventional VAV system without induction air and without the use of special VAV diffusers can only be turned down to 50/60% to prevent cold air dumping and maintain sufficient air movement and subsequently thermal comfort to the room in accordance with the strict international comfort standards (NEN, DIN, ISO, ASHRAE, etc.). Induction VAV can maintain these standards of thermal comfort at turndown ratio’s of 20%, this represents a considerable energy saving on running cost to the client.

Cooling mode

In cooling mode an Induction VAV system offers three main benefits over other VAV systems:

Reheat mode

Generally, VAV systems can only turn down to 50-60% to maintain thermal comfort in cooling mode. This unfortunately dictates that reheat must occur at 50-60% of Vmax. Reheating this high amount of primary air is very energy inefficient and costly.

Reheating with Induction VAV can occur at 20% of Vmax, this is close to the minimum fresh air requirement for a room. The system also takes advantage of heat reclaim from energy sources such as light fittings etc. by pre-heating primary air with induced air, this delays the reheat coil from energizing immediately, thus reducing reheat energy cost.

Looking for the right solution, use our selection software!

Specific questions about our systems or products? Feel free to contact us, we are happy to help you!